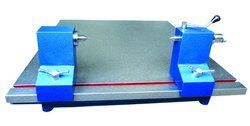

C.I Surface Plate with Bench Center

Product Details:

- Measuring Range Up to 1000 mm between bench centers

- Hardness Surface Plate: 170-220 HB (Brinell Hardness)

- Features High flatness, Sturdy cast iron construction, Rust resistant, Removable bench centers

- Temperature Recommended 20C 2C for highest accuracy

- Resolution 0.01 mm

- Power Supply N/A (manual equipment)

- Mounting Type Freestanding

- Click to View more

C.I Surface Plate with Bench Center Price And Quantity

- 1 Piece

- 2000 INR/Piece

- Gray or as per customer specification

- Cast Iron Base with ground steel centers

- Up to 10 microns/meter (as per grade 1 or 2)

- Bench centers, clamping devices (optional)

- Hand-scraped or precision ground to required grade

- Grade 0, Grade 1, Grade 2 (as per requirement)

- Yes

- High quality close-grained Cast Iron

- C.I Surface Plate with Bench Center

- Up to 150 mm (customized on request)

- IS:2285-2003, IS:2281

- Surface treated with anti-rust coating

C.I Surface Plate with Bench Center Product Specifications

- C.I Surface Plate with Bench Center

- 0.01 mm

- N/A (manual equipment)

- Freestanding

- Analog/Dial (for bench center)

- Approx. 200 kg - 600 kg (depending on model size)

- Cylindrical workpieces up to 1000 mm length (customized)

- Industrial precision inspection, metrology lab

- Immediate/Manual

- Varies by model (customizable)

- Manual

- Up to 1000 mm between bench centers

- High flatness, Sturdy cast iron construction, Rust resistant, Removable bench centers

- Surface Plate: 170-220 HB (Brinell Hardness)

- Recommended 20C 2C for highest accuracy

- Suitable for standard laboratory conditions

- Up to 1000 mm between centers (customized options available)

- As per IS:2285-2003 and IS:2281 standards

- Manual

- Precision measurement and inspection of cylindrical workpieces

- Gray or as per customer specification

- Cast Iron Base with ground steel centers

- Up to 10 microns/meter (as per grade 1 or 2)

- Bench centers, clamping devices (optional)

- Hand-scraped or precision ground to required grade

- Grade 0, Grade 1, Grade 2 (as per requirement)

- Yes

- High quality close-grained Cast Iron

- C.I Surface Plate with Bench Center

- Up to 150 mm (customized on request)

- IS:2285-2003, IS:2281

- Surface treated with anti-rust coating

C.I Surface Plate with Bench Center Trade Information

- 80 Piece Per Day

- 1-4 Week

Product Description

We are manufacturers, exporters & suppliers of high-quality Cast Iron Surface plate with bench center from Sonipat, India. We offer a vast range of superior quality Cast Iron Surface plate with bench center & bench centres, which are extensively used for general inspection work in metrology laboratories and other industries. Our range includes cast iron bench centre, Cast Iron Surface plate with bench center, mini bench centre, vertical bench centre, universal bench centre and many other. These bench centres are known for delivering better durability, reliability and performance in the defined operations. We are exporting Cast Iron Surface plate with bench center to various countries like Bahrain, Kuwait, Oman, Qatar, Saudi Arabia, the United Arab Emirates, Srilanka, Bangladesh, Russia, Australia, America, Germany, Romania & African countries.

Product details

| Finishing | Hand Scrapped Surface Finish |

| Size Of Plate | 630 x 630 mm to 2000mm |

| Material | Cast Iron |

| Brand | Luthra |

Specification

| Size Of Plate mm | Centre Distance mm | Centre Height mm |

| 750 x 600 | 400 | 125 |

| 1000 x 630 | 600 | 160 |

| 1000 x 1000 | 600 | 200 |

| 1000 x 1600 | 1200 | 160 |

| 1000 x 2000 | 1600 | 200 |

Superior Flatness and Accuracy

This surface plate exhibits exceptional flatness tolerance, up to 10 microns per meter, delivered either hand-scraped or precision ground as per IS:2285-2003 and IS:2281 standards. This guarantees precise reference for dimensional measurement, making it suitable for industries and metrology labs that require utmost accuracy.

Robust and Versatile Bench Center

The equipment includes a cast iron bench center with removable, ground steel centers, ideal for holding and inspecting cylindrical workpieces. Center heights and measuring capacities are customizable-up to 150 mm in height and up to 1000 mm between centers-accommodating diverse industrial requirements.

Designed for Longevity & Ease of Use

Built from high-quality cast iron with a Brinell Hardness of 170-220 HB, the surface is treated with an anti-rust coating for enhanced durability. The freestanding design ensures stability, while manual controls and optional bench center accessories enable straightforward, reliable operation in demanding environments.

FAQ's of C.I Surface Plate with Bench Center:

Q: How is the flatness of the C.I Surface Plate with Bench Center ensured?

A: The flatness is achieved through precision hand-scraping or grinding processes, and each plate adheres to rigorous IS:2285-2003 standards, offering up to 10 microns/meter flatness tolerance in Grade 1 or 2 depending on the requirement.Q: What are the main applications for this surface plate and bench center?

A: It is primarily used for precision measurement and inspection of cylindrical workpieces in industrial settings and metrology laboratories, providing a stable and accurate reference surface.Q: When should I choose between Grade 0, Grade 1, or Grade 2?

A: Selection should be based on the required measurement precision: Grade 0 is suitable for calibration labs, Grade 1 suits inspection rooms, while Grade 2 fits production environments with standard accuracy needs.Q: Where can the equipment be installed, and what is its mounting type?

A: The C.I Surface Plate with Bench Center is designed as a freestanding unit, making it suitable for installation in industrial workshops, metrology labs, and inspection areas.Q: What is the process for using the bench center with the surface plate?

A: Place the workpiece between the removable steel centers of the bench center, then secure it using clamping devices if required. The analog or dial display allows immediate measurements or inspections against the highly flat reference surface.Q: How does the anti-rust treatment benefit the surface plate?

A: The anti-rust surface treatment protects the cast iron from corrosion, thus ensuring longevity and consistent performance even in environments with humidity or exposure to coolants.Q: What are the usage and benefits of vibration resistance in this product?

A: Vibration resistance stabilizes the equipment during use, maintaining the accuracy of measurements and protecting both the plate and sensitive instrumentation attached to or placed on it.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free